We are Authorized Channel Partners, Distributor, Dealer, Importer for Micro Detectors, Ultrasonic Sensors from Pune, Maharashtra, India.

|

||||

| • Up to 2,200 mm sensing distance range • Models with digital output (single or double) or analogue output (I/V) available • Synchronization and multiplexing functions • Plastic or AlS1316L stainless steel housing • Cable or M12 plug exit • Models with radial emission • Models with 10-LINK technology |

|

|||

|

||||

| • Up to 3,500 mm sensing distance range • Models with digital output (single or double), analogue output (IN) or mixed output (digital + analogue) available • Plastic or AISI316L stainless steel housing • Cable or M12 plug output. Models with 10-LINK technology |

|

|||

|

||||

| • Up to 1,200 mm sensing distance range • Reduced deadband • Models with digital and analogue output (I/V) • Plastic or AISI316L housing. Cable or M12 plug output • Models with 10-LINK technology |

|

|||

|

||||

| • Up to 8,000 mm sensing distance range • Models with digital (single or double), analogue or mixed (digital + analogue) output • Plastic or AlS1316L housing. Cable or M12 plug output • Models with 10-LINK technology |

|

|||

|

||||

| • Models with 0- 300 mm or 0-1,100 mm sensing distance range • Housing with reduced dimensions • Cable exit • Ultrasonic fork sensors for label detection on transparent surfaces • Dynamic Teach-in system • Width slit detection 3 mm; maximum switching frequency 1,500 Hz |

|

|||

|

|||

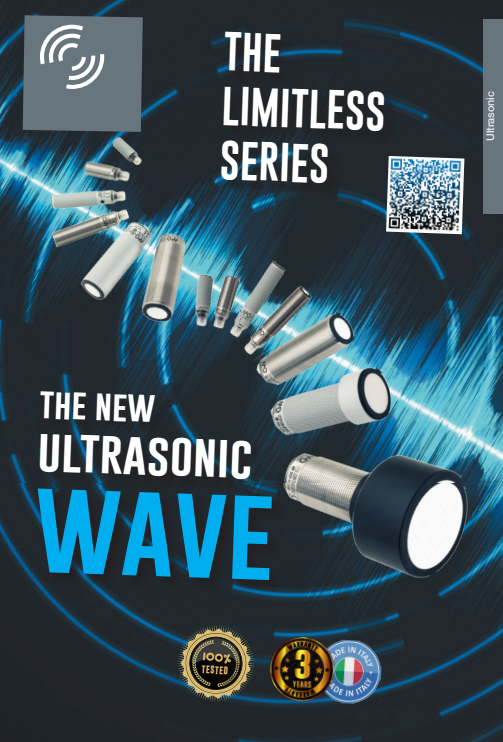

| Operation principle of Ultrasonic Sensors | |||

|

|||

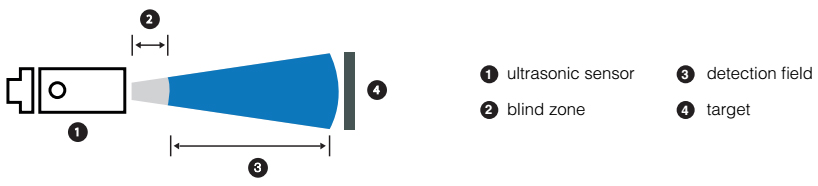

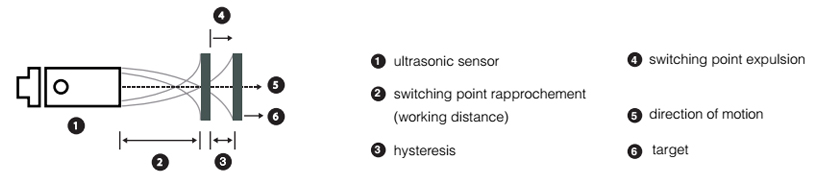

| Ultrasonic sensors are composed by: ultrasonic transducer, oscillator, trigger circuit and output circuit. There are three working principles: • Direct Diffusion Ultrasonic transducer is energized by high voltage pulses and starts to emit an ultrasonic signal. The ultrasonic signal is reflected by the target towards the sensor. Trigger circuit measures the time between the emission and the detection of the signal. Since the speed of the ultrasonic beam in air is known, it is easy to have not only an indication of the presence of the target, but also a measure of the distance between sensor and target. In diffuse models, the ultrasonic transducer works before as emitter and then as receiver. When it is in "emission mode" no signal can be detected. This imply that in front of the sensor there is a blind zone where the detection of objects is not possible or not reliable. The dimension of the blind zone depends on the type of ultrasonic transducer used. |

|||

|

|||

• Retroreflection • Emitter and receiver Considerations on argets tipology |

|||

|

|||

|

||||

| • Models with digital programmable output • Models with current or voltage analogue outputs • Adjustable Hysteresis function: model with programmable double digital outputs, specific for levels • Working area adjusting (window teach or single point teach) by Teach-in button suitable for all models for a fast coming into work • Multifunction LED indicator: output type. adjustment procedure, NO/NC selection and reverse analog output slope |

|

|||

|

||||

• M18 diffuse sensors with short housing |

|

|||

|

||||

• M30 ultrasonic sensor with standard housing and with large front with high performances and high sensing distances

|

|

|||

|

|||||

• Total protection against any of electric damages |

|

||||

|

|||||

|

|||||

Read more products :