We are Authorized Channel Partners, Distributor, Dealer, Importer for REER Safety Sensors from Pune, Maharashtra, India.

• Ensuring operator and machine safety

• No special actuator requird

• Connection to Safety PLC or Safety Controller

|

||||

| Guaranteed safety PI-Safe safety sensors increase the uptime and safety of installations and can be connected to approved evaluation units without cross-fault monitoring. |

||||

|

||||

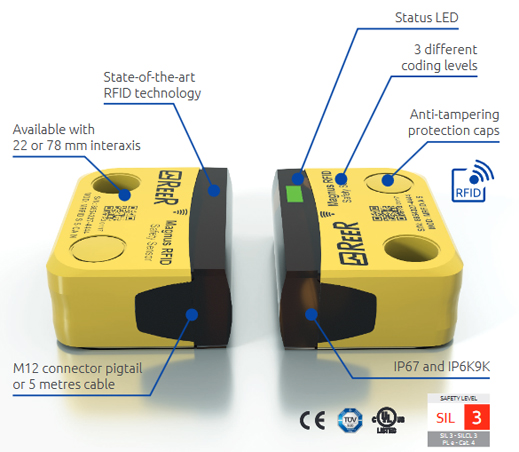

Next Generation Sensors for Machine Safety - Magnus RFID

Next Generation Sensors for Machine Safety - Magnus RFID

The best in cost-effectiveness The best in safety The best in versatility Magnus RFID - next generation The different design and technology options as well as the complete mechanical compatibility with the Magnus MG magnetic sensors series, make this product extremely valuable for users. The RFID technology enables Magnus RFID sensors to be individually coded in three different ways to allow the appropriate tampering protection in all applications. The highest configurations allow each sensor to be paired with one only assigned actuator. The RFID technology used allows to reach safety levels up to PL e/SIL 3 also when connecting the sensors in series. As a result, Magnus RFID sensors can be simply integrated in existing safety scenarios, offering a cost-effective solution for modifying and upgrading machines. |

||||

|

|||

Magnus RFID is the ideal choice formany industrial applications, including food & beverage, packaging, pharmaceutics, printing, paper, logistics,renewable energies, chemicals, injection moulding and many more ...

|

|||

Read more products :